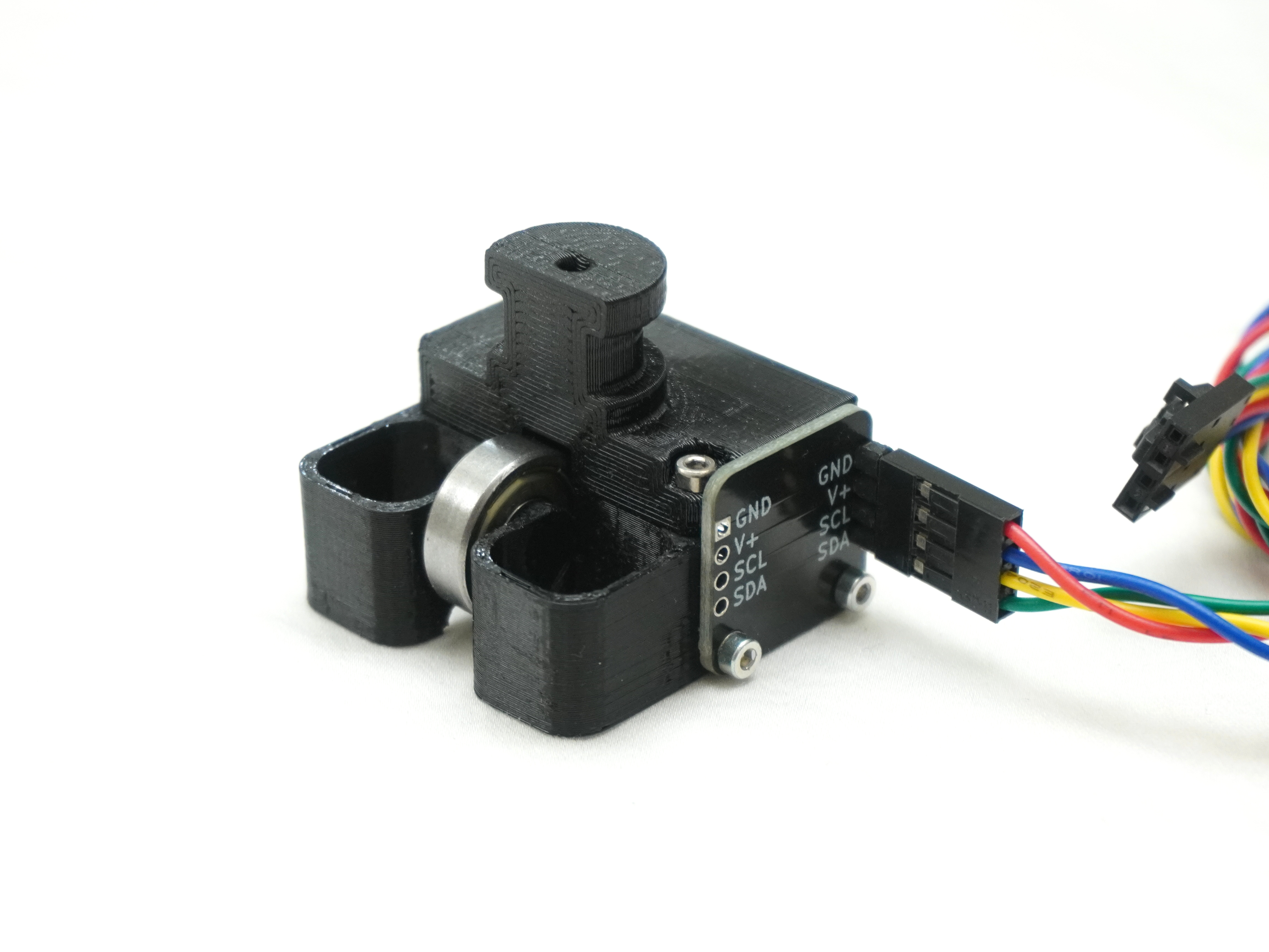

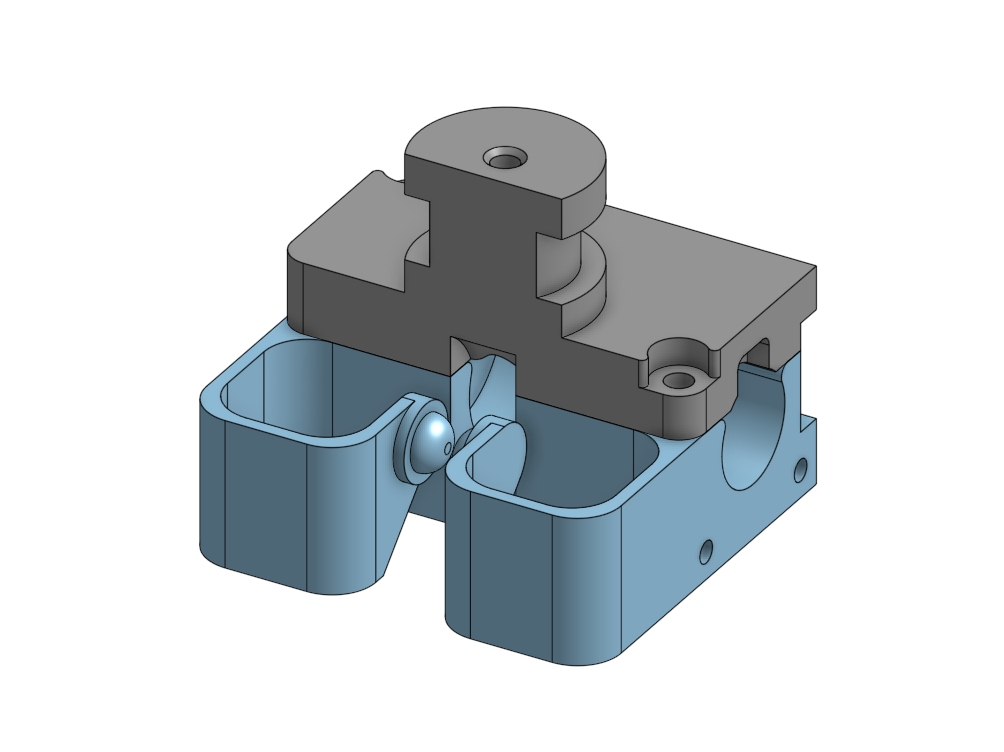

Sensor that allows 3D printers to detect filament jams and runouts. Allows for closed loop control of extrusion. Printer can take pause or take action if a problem is detected, and also automatically calibrate extrusion amount while printing. Uses a magnetic hall effect angle sensor to detect the rotation of a gear driven by the filament. Minimizes components by using a compliant mechanism to press and idler wheel against the filament, which in turn spins the sensor gear. Interfaces with the printer’s controller using I²C.

Responsibilities #

- Mechanical design (CAD) in Onshape

- Electrical PCB design in KiCad

- Wrote driver for Smoothieware to interface with sensor via I²C